Our broken tool monitoring systems ensure that your products always provide absolute top quality.

Fully functioning tools are essential for quality materials processing. When you choose our broken tool monitoring equipment you are making the best decision to control your processes and ensure the quality of your products. Our scanning systems have been specifically designed to monitor different sizes of tools. We will select the right system for your project from our standard range, or if required we will design it to meet your specifications or develop a tailor-made solution just for you.

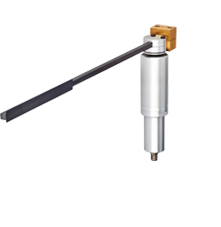

As part of our automated monitoring system, a scanning probe sweeps at a defined angle towards the tool after it is retracted. If the probe detects resistance from the tool, an “OK” signal is generated. The system immediately recognizes if there is no resistance and the tool is broken, generating a “Not OK” signal. The machining process is immediately stopped. This avoids bad parts, wasted production time, and quality problems. They also recognize when work pieces are incorrectly positioned, preventing damage to the machines and tools. We have many satisfied customers worldwide, mainly in the engineering and automotive industries, who use our robust and maintenance-free monitoring systems as part of their quality control processes.

Our systems are fully sealed, which ensures that none of the moving parts can be blocked with swarf or other debris. Ideally, our technology should be integrated into the machinery during the manufacture, or our systems can also be retrofitted at a reasonable cost.

As part of our special customer service program, we can usually supply you with spare parts even 30 years after series production has ended.